What is PROFIBUS and its purpose?

Definition and Overview

Profibus stands for Process Field Bus, a widely used communication protocol in industrial automation. It facilitates data exchange between various devices within a manufacturing or process environment.Historical Background

Profibus was developed in the 1980s by a consortium of German companies. Since then, it has evolved into a standard for industrial communication, offering reliability and versatility.Importance in Industrial Automation

Profibus plays a crucial role in modern industrial automation by enabling efficient communication between sensors, actuators, controllers, and other devices. It enhances productivity and reduces downtime in manufacturing processes.Types of Profibus

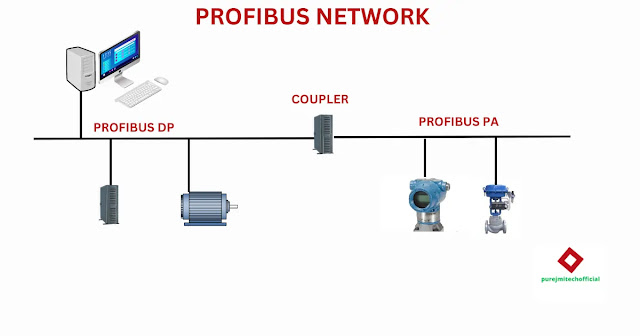

- Profibus-DP (Decentralized Peripherals)

- Profibus-PA (Process Automation)

- Profibus-DPV1 (Decentralized Peripherals Version 1)

Profibus-DP (Decentralized Peripherals)

Profibus-PA (Process Automation)

Profibus-PA is designed for process automation applications, providing robust communication for sensors and actuators in hazardous environments such as chemical plants and oil refineries.

Profibus-DPV1 (Decentralized Peripherals Version 1)

Profibus-DPV1 extends the capabilities of Profibus-DP by enabling the exchange of diagnostic information and parameterization data, enhancing system diagnostics and maintenance.

Architecture of Profibus

- Physical Layer

- Data Link Layer

- Application Layer

Physical Layer

Data Link Layer

The data link layer of Profibus ensures reliable transmission of data packets between devices, implementing error detection and correction mechanisms to maintain data integrity.

Application Layer

The application layer of Profibus defines the communication protocol and data exchange formats used by devices, enabling seamless interaction within the industrial automation ecosystem.

Profibus Network Components

- Master Devices

- Slave Devices

- Repeaters

- Couplers

Master devices in a Profibus network, such as PLCs or industrial PCs, control the communication process and coordinate data exchange with slave devices.

Slave Devices

Slave devices, including sensors, actuators, and other field devices, communicate with the master device to send and receive data, enabling real-time control and monitoring.

Repeaters

Repeaters amplify and retransmit signals within a Profibus network, extending the communication range and ensuring reliable data transmission over long distances.

Couplers

Couplers facilitate communication between different Profibus segments or protocols, enabling seamless integration of diverse industrial automation systems.

Communication Protocol of Profibus

- Data Exchange Methods

- Telegram Structure

- Addressing Mechanisms

Data Exchange Methods

Profibus supports various data exchange methods, including cyclic, acyclic, and time-critical communication, catering to different application requirements in industrial automation.

Telegram Structure

The telegram structure of Profibus defines the format and content of data packets exchanged between devices, ensuring efficient communication and interoperability within the network.

Addressing Mechanisms

Profibus uses unique addresses to identify devices within the network, enabling targeted communication and data exchange between specific devices as required by the application.

Profibus Topologies

- Bus Topology

- Star Topology

- Tree Topology

In a bus topology, all devices are connected to a single communication line, enabling straightforward installation and cost-effective communication in small to medium-sized networks.

Star Topology

Star Topology

In a star topology, devices are connected to a central hub or switch, offering enhanced reliability and scalability for larger Profibus networks with multiple segments.

Tree Topology

A tree topology combines elements of bus and star topologies, allowing for flexible network design and efficient communication in complex industrial automation environments.

Advantages of Profibus

- High-Speed Communication

- Flexibility in System Configuration

- Cost-Effectiveness

Profibus provides high-speed communication, enabling real-time control and monitoring of industrial processes, improving productivity and efficiency.

Flexibility in System Configuration

Profibus offers flexibility in system configuration, allowing for easy integration of new devices and modifications to existing setups, reducing downtime and maintenance costs.

Cost-Effectiveness

Profibus is a cost-effective solution for industrial communication, offering reliable performance and scalability at a competitive price point compared to alternative technologies.

Diagnostic Capabilities

Profibus supports advanced diagnostic features, enabling proactive maintenance and troubleshooting of industrial automation systems, minimizing downtime, and improving reliability.

Applications of Profibus

- Manufacturing Industries

- Process Automation

- Building Automation

Manufacturing Industries

Profibus is widely used in manufacturing industries such as automotive, pharmaceuticals, and consumer electronics, facilitating efficient production processes and quality control.

Process Automation

Profibus is utilized in process automation applications such as chemical processing, oil and gas refining, and water treatment, ensuring reliable communication and control in harsh environments.

Building Automation

Profibus finds applications in building automation systems, enabling efficient management of HVAC (Heating, Ventilation, and Air Conditioning), lighting, and security systems in commercial and residential buildings.

Comparison with Other Industrial Communication Protocols

Profibus vs. ModbusProfibus offers higher communication speeds and more advanced features compared to Modbus, making it suitable for demanding industrial automation applications.

Profibus vs. Ethernet/IP

Profibus and Ethernet/IP both offer robust communication for industrial automation, with Profibus being more widely adopted in legacy systems and Ethernet/IP gaining popularity in newer installations.

Profibus vs. CANopen

Profibus and CANopen serve different application requirements, with Profibus offering higher communication speeds and broader compatibility for industrial automation compared to CANopen.

Challenges and Limitations

Interference and Noise IssuesProfibus networks may face challenges such as electromagnetic interference and signal noise, requiring proper shielding and grounding to ensure reliable communication.

Limited Bandwidth

Profibus has a limited bandwidth compared to newer communication protocols, which may become a bottleneck in high-density industrial automation systems with a large number of devices.

Complexity in Large Systems

Managing large Profibus networks can be complex, requiring careful planning and configuration to ensure optimal performance and reliability across multiple segments and devices.

Future Trends in Profibus Technology

Integration with Industrial IoT (IIoT)

Profibus is evolving to integrate with Industrial IoT (IIoT) technologies, enabling seamless connectivity and data exchange between industrial automation systems and cloud-based platforms for advanced analytics and decision-making.

Enhancements in Communication Speed

Future developments in Profibus technology are expected to focus on enhancing communication speeds and bandwidth, catering to the increasing demand for real-time control and monitoring in industrial automation.

Adoption of Wireless Profibus

Wireless Profibus technologies are emerging to address the need for flexible and scalable communication solutions in industrial automation, enabling remote monitoring and control without the constraints of wired connections.

Conclusion

Summary of Key Points

Profibus is a versatile communication protocol widely used in industrial automation, offering high-speed communication, flexibility in system configuration, and advanced diagnostic capabilities.

Profibus is a versatile communication protocol widely used in industrial automation, offering high-speed communication, flexibility in system configuration, and advanced diagnostic capabilities.

Importance of Profibus in Industrial Automation

Profibus plays a crucial role in enhancing productivity, efficiency, and reliability in various industrial sectors, driving innovation and advancements in manufacturing and process automation.

Potential for Future Developments

With ongoing advancements in technology and increasing adoption of Industrial IoT (IIoT) solutions, Profibus is poised to continue evolving to meet the evolving needs of industrial automation, ensuring seamless connectivity and communication in the digital age.

FAQs

What is Profibus PA Speed?

Profibus PA segment runs at 31.25Kbit/sec.What is Profibus PA Physical Layer?

Profibus PA Physical Layer is IEC 61158-2.

What are the advantages of PROFIBUS DP?

Profibus DP (Decentralized Peripherals) offers several advantages in industrial automation and control systems:

- High-Speed Communication

- Flexibility

- Reduced Wiring

- Diagnosis and Maintenance

- Interoperability

- Scalability

- Cost-Effectiveness

What is DP in communication?

Profibus DP (Decentralized Peripherals) is a widely used field bus communication protocol for connecting devices such as sensors, actuators, drives, and controllers in industrial automation systems.

Post a Comment